Fire Windows

Fire windows are one of the main factors determining a structure’s resistance to fire. Much depends on design decisions and the chosen structures. One of these is fire windows, which often go unnoticed in daily life but are critically important in emergency situations. A fire in a room can heat the air to 600–800 °C within minutes. If the structures are not adapted, glass shatters, flames and smoke enter other spaces, and evacuation becomes difficult or even impossible. Fire windows are designed to contain the fire, provide time for rescue operations, and protect adjacent structures from overheating.

Our certifications

Fire windows are special structural windows designed to withstand the effects of fire and high temperatures for a specific period: from 30 to 90 or even 120 minutes. They contain flames and smoke, preventing their spread to other rooms or evacuation routes.

How are Fire Windows Made?

The production of fire windows uses heat-resistant aluminum profiles that do not burn and maintain structural stability even at high temperatures. Special multi-layered glass with intumescent layers is also installed – in the heat, these materials expand and create a thermal barrier.

The glass units can be 24–60 mm thick, usually composed of several tempered or laminated glass panes with fire-resistant layers inserted between them. Additionally, fire-resistant sealing gaskets and adhesives are used, which maintain tightness even at extremely high temperatures.

Advanced Systems and Materials

Additionally, fire windows can utilize systems like the MB-86 EI, designed for manufacturing fire-resistant windows, doors, and partitions, ensuring EI30 and EI15 fire resistance classes. These systems are characterized by excellent thermal insulation properties (Uf from 1.07 W/(m²K) to 0.86 W/(m²K)), good airtightness, and triple-glazed profiles with a thermal break zone and special fire-resistant infill materials increase the structure’s resistance to both fire and environmental impact.

Fire windows can be designed with glazing solutions using tempered, laminated, or multi-layered glass with intumescent layers, which create a strong insulating barrier at high temperatures. Such solutions are applied to both internal and external fire-resistant applications where it is necessary to combine fire-resistant properties, sound insulation, and energy efficiency.

Design and Aesthetics

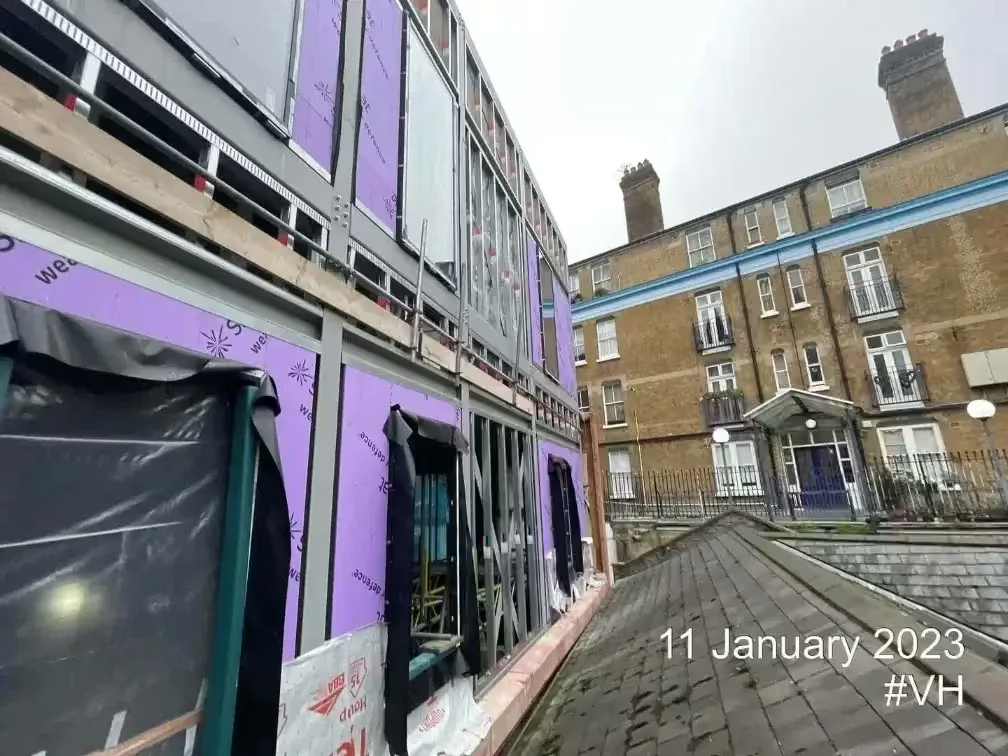

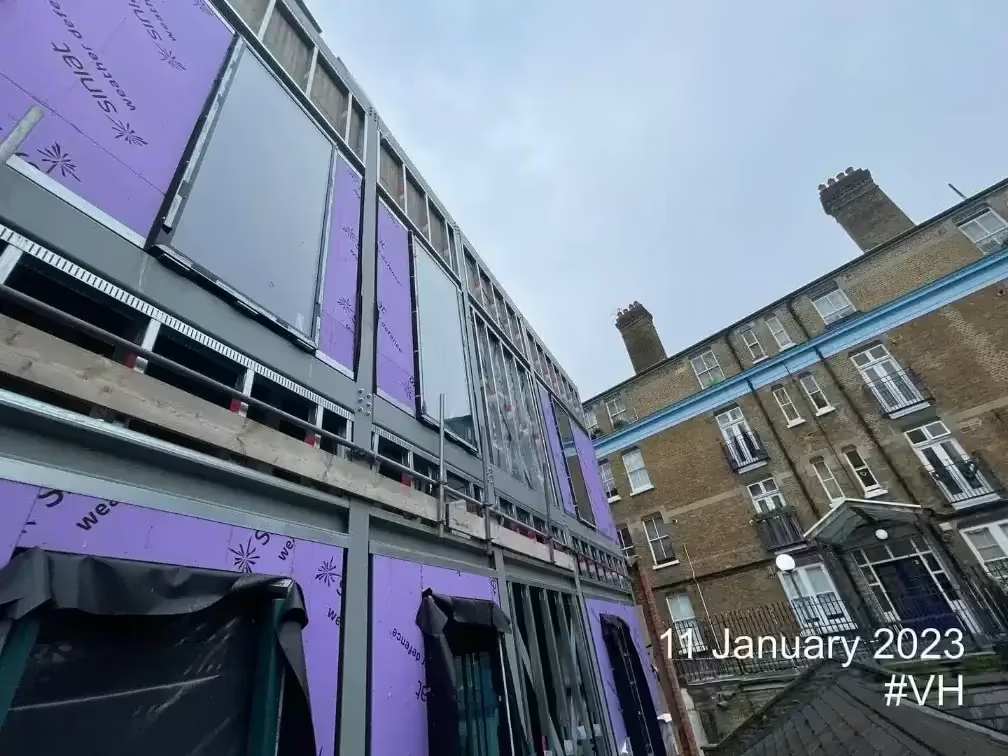

Many people imagine fire windows as massive and cumbersome. Modern aluminum constructions are changing this perception. Aluminum fire windows look just as elegant as regular ones because the profiles can be minimal, painted in any RAL palette color, or covered with a wood-imitation film. Therefore, project developers and architects can combine safety with aesthetics without any compromise.

Additionally, fire windows can be integrated into facade profiles, allowing for the formation of both flat and angled fire-resistant glass walls and skylights. These systems provide architects with broader design possibilities by maintaining a unified aesthetic appearance of the facade, even if part of the glazing has fire-resistant properties while another part is standard.

MB-86 EI Fire-Rated Windows

The MB-86 EI system includes a window solution designed to meet fire resistance classifications of EI15 and EI30 in accordance with EN 13501-2. These windows are intended for use in external or internal fire-rated partitions where both fire protection and thermal insulation are required.

Fire Resistance

Fire-rated windows in the MB-86 EI system use aluminum profiles that are reinforced with special fire-resistant inserts and intumescent components. These materials help maintain fire integrity for 15 or 30 minutes, depending on the design. Fire resistance is maintained whether the window is exposed to fire from the inside or outside.

The profiles are designed to house a wide range of fire-resistant glazing options, supporting glass thicknesses depending on the specific configuration. This makes the system adaptable to different project needs.

Continue reading

Thermal and Acoustic Performance For Fire Rated Windows

The MB-86 EI D system uses profiles with thermal breaks measuring 42 or 43 mm, creating an internal insulation zone. This helps achieve low heat transfer values:

– Thermal transmittance (Uf) from 1.07 W/(m²K) down to 0.86 W/(m²K) depending on the configuration.

In addition to thermal performance, the construction also helps reduce sound transmission.

Air, Water, and Wind Resistance

The door system has been tested for resistance to external elements and meets the following classifications:

Air Infiltration: Class 4 (EN 12207)

Water Tightness: Class E1350 Pa (EN 12208)

Wind Load Resistance: Class C1/B1 (EN 12210)

These properties make the windows suitable for use on building exteriors in various climates.

Fire Door Security and Glazing Options

Fire Windows in the MB-86 EI D system can be fitted with double or fire-rated glazing, depending on project requirements. The profiles allow for different glass thicknesses and use steel holders, fire-resistant shims, and EPDM gaskets for tight and secure installation.

Standard door fittings meet the RC2 burglary resistance class, providing a basic level of security for most building types.

Where Can Fire Rated Windows Be Applied

MB-86 EI W windows are used in places where both fire safety and thermal insulation are required, such as:

– Entrances and exits in public or commercial buildings

– Fire escape routes

– Internal compartmentalization between fire zones

– Areas where smoke control or delayed fire spread is needed

Smoke Exhaust Fire Windows

Smoke exhaust windows are designed to support fire protection strategies by enabling fast removal of smoke and heat during emergencies. When activated, these windows open to release smoke and hot gases, helping maintain clearer escape routes and improving visibility for evacuation and rescue operations. They also assist in reducing temperature buildup, slowing fire spread, and protecting structural elements.

Function and Use

These windows can be used as part of gravity ventilation systems or combined with fire safety systems to serve dual purposes: everyday ventilation and emergency smoke exhaust. You can use these windows in, Stairwells, Corridors, Atriums, Industrial spaces, Skylights and façade areas

They are commonly integrated into aluminum façade systems or installed as part of sloped roof glazing.

Continue reading

Fire Window System Compatibility

Smoke exhaust windows are available in multiple Aluprof window systems, including:

– MB-59S and MB-59S Casement

– MB-60 and MB-60US

– MB-70 and MB-70US

– MB-86 and MB-86US

– Façade-specific configurations like slope-mounted or roof window types.

This allows them to be matched to other architectural elements within a building envelope and maintain a consistent design.

Fire Window Opening Types and Operation

Depending on the system and installation position, smoke exhaust windows can be configured as:

– Side-hung

– Bottom-hung

– Top-hung

– Roof windows in sloped applications

They use mechanisms from manufacturers like D+H, GEZE, and ESCO, and support a variety of actuators:

– Chain, spindle, or rack mechanisms

– Single, double, or triple drives

– Opening forces up to 3,000 N

– Synchronised “Tandem” setups for large or wide openings

These systems are designed to operate reliably and quietly. The maximum opening angle is up to 90°, ensuring efficient smoke extraction.

Integration and Control

The windows are compatible with:

– Building automation systems

– Fire alarm systems

– Emergency power supply units

– Manual and automatic control panels

Additional safety features include:

– Anti-crushing protection

– High-speed opening options

– Discreet actuators mounted parallel to the window for a clean appearance

Window Profile Construction

The window frames are made from thermally insulated aluminum with a triple-glazed profile design.

A central insulation zone is placed between thermal breaks measuring 42 or 43 mm, improving heat performance.

The profiles also include components that provide fire protection between the frame and the glass.

These design elements contribute to both fire safety and energy efficiency.

Fire Window Thermal and Weather Performance

The MB-86 EI windows offer high performance in energy conservation and resistance to external elements:

– Thermal insulation: Uf values from 1.07 W/(m²K) down to 0.86 W/(m²K) depending on the profile configuration.

– Air infiltration: Class 4 (EN 12207)

– Water tightness: E1500 Pa (EN 12208)

– Wind load resistance: Class C5 (EN 12210)

These values make the windows suitable for use in buildings that require both fire safety and thermal control, including energy-efficient buildings and those in demanding weather conditions.

Fire Window Security

The MB-86 EI system uses RC2-rated hardware for its standard window fittings. This level of burglary resistance offers a basic layer of physical security, which is beneficial in public, commercial, or residential buildings where window security is important.

Application and Integration

MB-86 EI windows are designed for integration with other systems in the MB-86 family, allowing a consistent appearance and shared installation process when used alongside matching doors or partitions. This helps reduce fabrication time and simplifies system compatibility across a project.

These windows are suitable for use in:

– Office buildings

– Hospitals

– Public institutions

– Residential buildings

– Fire compartment zones and escape routes

Why work with us?

We are experts in aluminum systems. We design, manufacture, and install high-quality fire-resistant windows that meet the strictest safety requirements.

- Products tailored for the Lithuanian market

- We manufacture everything ourselves – from start to finish

- More than 100 completed projects

- Engineering solutions you can trust

Fire Windows and Sustainability

Aluminum is a 100% recyclable material, and fire-resistant glass is also created with the lowest possible emissions during production. This means that by choosing aluminum fire windows, you contribute not only to safety but also to sustainable development goals.

Additionally, the systems are designed to meet not only fire regulations but also modern energy efficiency standards, thus contributing to improving the overall energy class of buildings and reducing CO2 emissions in the long term.

Installation – A Critical Part of Success

Even the best fire window will lose its function if it is improperly installed. During installation, it is important to ensure correct sealing, fastening, and compliance with certification requirements. The Alugama team ensures a complete process: from design consultation to professional installation and quality control.

Why Choose Alugama?

By choosing Alugama, you get more than a window. You get:

Experience and professionalism. We work with certified suppliers and know the subtleties of every project.

Versatility. We can offer solutions for both commercial and residential properties.

Peace of mind. You know that your windows meet all legal requirements and genuinely protect human lives.

Other Products

Frequently Asked Questions

What types of fire-rated window glazing is there?

There are two main types: fire-protective glazing (blocks flames and smoke) and fire-resistive glazing (blocks flames, smoke, and heat). Fire-resistive glass is used in stricter fire compartments or walls with ratings above 60 minutes.

What fire resistance window ratings are available?

Typical ratings include 30, 60, 90, 120, and 180 minutes, depending on the building code requirements and product certification (e.g. EN 13501-2 or UL 9).

When and where are fire-rated windows required by code?

Fire-rated windows are typically required in fire barriers, stairwells, corridors, and exterior walls near property lines, where building regulations demand compartmentalization to prevent fire spread.

Can fire windows cover more than 25% of a wall?

Most codes limit fire window openings to 25% of the fire-rated wall unless additional fire protection (like sprinklers) is in place or the glass meets stricter criteria.

Do fire-rated windows need permanent labels or certifications?

Yes, all fire-rated windows must include permanent, visible labels indicating the fire rating, testing standard, and certifying body (e.g. UL, CE, EN).

What materials are typically used in fire window assemblies?

Fire windows use heat-resistant glass (such as wired, ceramic, or intumescent-layered glass) and frames made of steel or specialized aluminum with fire-resistant seals and hardware.

Can aluminum frames be used for fire-rated windows?

Yes, with proper insulation and design, aluminum frames can meet fire ratings up to 60 or 90 minutes, especially when combined with fire-rated glazing and seals.

What is the difference between fire-protective and fire-resistive glazing?

Fire-protective glazing blocks flames and smoke but allows radiant heat to pass through. Fire-resistive glazing blocks heat as well, making it suitable for higher-risk areas.

How do fire-rated windows perform in extreme conditions?

They are designed to withstand intense heat and thermal shock for a specific period without shattering or allowing fire to pass. However, performance depends on correct installation and sealing.